Finally getting around to making progress on another engine. It’s only a matter of time before my engine finally gives up. It’s covered 100k km since I’ve had it, but no firm details on when it was rebuilt before I got it.

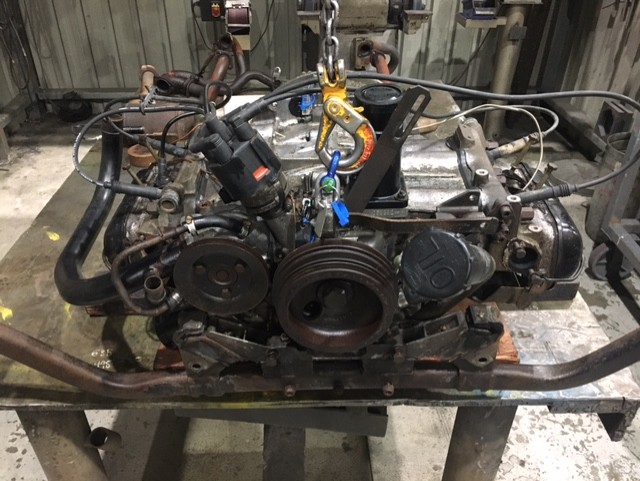

After collecting bits and pieces of two engines, both would need a lot of work and parts to resurrect. A complete engine from a 2WD sold to me as a good engine, but it has been sitting for a very long time, finally picked up a Syncro engine (thanks Grant!!).

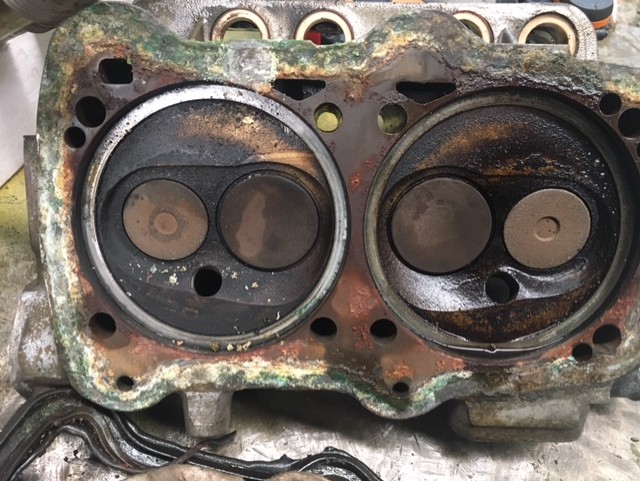

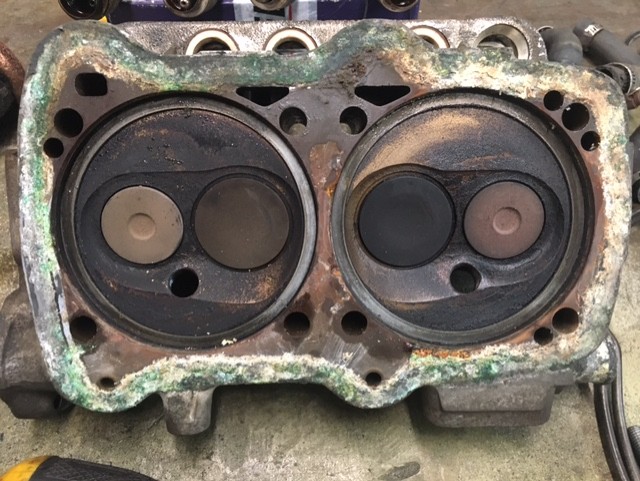

Given the issues these engines can have, made the decision I would give this a good tidy up before installing. A lot of bits needed going over, the exhaust was quite rusty and I figured it would be good to replace what seals I could while it was out. As with any job on old cars, once you start, you open a whole can of worms! The worst of which was finding green coolant in the engine. So I’ve taken the heads off to have a deeper look.

I’m guessing the green coolant had not been in for long as corrosion had only just started. Coolant pipes, engine block etc all looked OK. There was a bit of corrosion in the water pump, but corrosion had already started on the heads. Just goes to show even though things appeared fine, and the coolant came out very clean, the rot had begun!

Slowly going through it all, everything so far looks in spec, crank end float, ring gap etc. Still have a bit more checking, but so far so good. No evidence of cracks in the heads but will put a die test on them once I’ve cleaned them up.

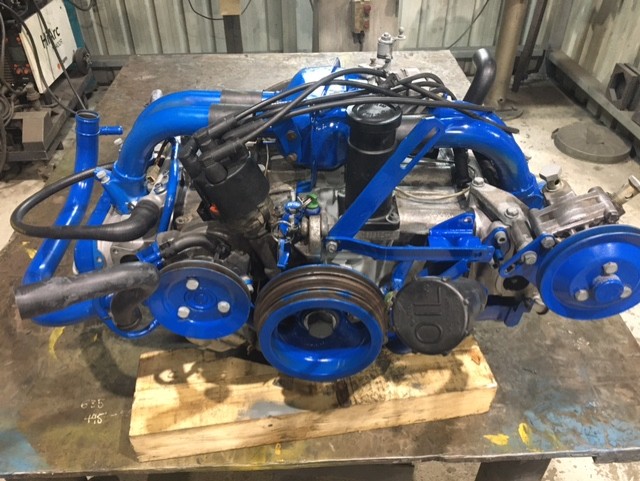

Exhaust and bits and pieces patched up as needed and cleaned and painted ready to go.