Hi there folks.

I thought it best to start a build thread on this 1990 ex Telsta Syncro i acquired from a deceased distant family member.

I thought this might be a reasonably quick and easy project as she is almost 100% rust free.

Oh how wrong I was.

After an hour of drivers door latch disassembly and WD40 I was able to close the door.

Then i focused on seeing if i could get it running.

My father in law had already charged up the dual batteries but had no luck strating it, wouldn’t even crank over.

I did all the usual checks, oil, water, air cleaner. Everything looked complete.

Before I even tried the key, I had a look at the battery terminals and they both have isolator screws on the negative terminal, so I gave them a tighten and that must have been what stopped my father in law.

After a longish amount of cranking she eventually fired up and went into a high idle, with a lifter tick and a soft backfire at idle and low rpm. The lifter tick went away after a few minutes but the backfire continued, my guess was a burnt exhaust valve.

After a few drives up and down the driveway, then the street. I deemed it sturdy enough to attempt the 90km drive home with my father in law following behind.

The gear stick was very difficult to move and I made a mental note to order new shift rod bushes.

At some point I noticed the speedo wasn’t working, so I had my phone on for speed, but I shouldn’t have worried, these things have low gears eh? I dont think I got over 85kph on the freeway as I babied her home.

Shortly before the turn off freeway an alarm buzzer went off with a flashing red LED.

So I pulled over and shut her off.

A quick search online indicated low oil preasure at slow cruise.

But the aftermarket oil preasure gauge seemed to be functioning and I opted to limp on home.

Thinking I was likely going to be doing some sort of engine work anyway with the suspect burnt valve which may have cleared itself up by this point, but the buzzer was the only thing I could hear.

Over the next few days I started researching and inspecting the various issues.

I inspected the shift rod bushes and they apeared to be pretty fresh, turned out the plates that hold the bust at the tranaxle were both on the same side of the mounting bracket and were squishing the bush onto the rod without the space of the mount between them.

Easy victory.

Next was the speedo, speedo cable was unplugged from speedo, nope, didn’t fix it, maybe it’s broken… let’s have a look at the other end… hey, where’s the front diff? And CV axles and prop shaft? How did I not notice them missing while working on the shift rod bush?

As some of you will already know, I’ve been trying to track down a front diff.

My aim upto this point was to get her fixed up enough for a roadworthy and club registration.

Deal with an engine rebuild or Subie swap later.

The more I researched, the more I realised how much of a short production run these quirky VW’s had. And how rear NOS parts are.

Coming from the air cooled VW scene, parts are pretty easy to get hold of.

Lucky there are many passionate and helpful enthusiasts out there. A big thanks to those on here who have already offered advice and answered questions.

Last weekend I was lucky enough to get back to her original home and a search of the garden shed revealed the front diff all wrapped up in plastic, the prop shaft, mounting cradles with hardware, even the rest of the CV axles after they were taken apart to make front hubs.

I didn’t fancy trying to put CV’s back together, so I ordered what appear to be the last pair of front VC axles in Australia at the moment. 2 days from QLD is pretty good.

I resisted the urge to just bolt it all up and hope for the best.

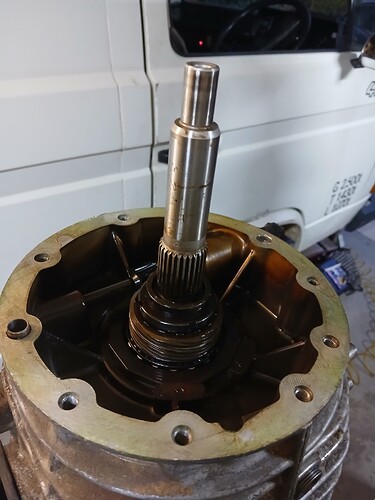

I started cleaning up the diff with the intention of at least changing the oil.

By this point I was pretty sure the Viscous Coupling wasnt working, as the input shaft span freely by hand and transferred nothing to the final drive. Also, why else would someone remove the front diff and convert to 2wd?

My thinking at this point was to try to identify and track down the shaft seals for the VC and some of this magical silicone fluid and hopefully someone would be able to tell me how much air gap to leave.

Now I have to learn how to upload photos again…